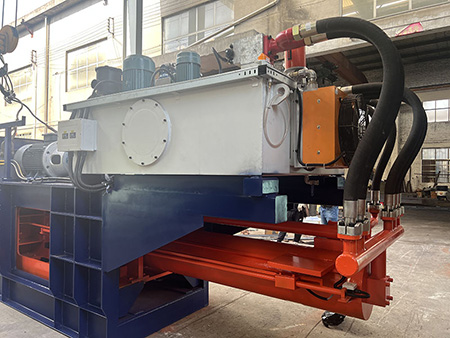

Automatic Baling Press Machine

The automatic waste paper baler is a completely unmanned operation and is suitable for places with a lot of materials. After the articles are compressed and bundled, they are easy to store and stack and reduce transportation costs. The unique automatic strapping device of the automatic waste paper baler is fast, simple in structure, stable in action, low in failure rate and easy to maintain. The automatic waste paper baler is suitable for waste paper cartons, plastics, fabrics and large garbage disposal places.

The automatic waste paper baler production line is composed of the main machine, conveyor, hopper, and air cooling system.The automatic waste paper baler has stable performance, high cost performance, simple operation and good safety performance. It is suitable for Baler all kinds of waste cardboard,

waste paper boxes, waste paper shells, waste paper barrels, waste paper edges, waste plastics, and other waste garbage into blocks to achieve cost saving and convenient transportation.

1. All NICKBALER models are hydraulically driven.

2. Fully automatic unmanned operation, automatic baling press and unpacking, high work efficiency

3. The full English version of the operation interface allows you to see at a glance

4. Adopt servo system control, advanced technology and simple operation

5. The motor box is set reasonably and beautifully

6. Equipped with detailed operating instructions and obvious safety prompt signs

7. The equipment is stable and no foot screws are required for installation

|

Item |

Name |

parameter |

|

mainframe parameter |

Bale size | 1100mm(W)×1100mm(H)×~1800mm(L) |

| Material type | Scrap Kraft paper, Newspaper, Cardboard ,Soft Film, Plastic, | |

| Material density | 650~750Kg/m3(Moistures 12-18%) | |

| Feed opening size | 2400mm×1100mm | |

| Main motor power | 37KW×2sets+15KW | |

| Main cylinder | YG300/230-2900 | |

| Main cylinder force | 200T | |

| Capacity | 28-30Ton/hour | |

| Max. system working force | 30.5MPa | |

| Mainframe weight(T) | About 30 tons | |

| Oil tank | 2m3 | |

| Mainframe size | About 11×4.3×5.8M(L×W×H) | |

| Tie wire line | 4 line φ3.0-3.2mm3 iron wire | |

| Pressure time | ≤30S/ (go and back for empty load) | |

|

Chain conveyor technology |

Model | NK-III |

| Conveyor weight | About 7 tons | |

| Conveyor size | 2000*14000MM | |

| terra hole size | 7.303M(L)×3.3M(W)×1.2M(deep) | |

| Conveyor motor | 7.5KW | |

|

Cool tower |

Cool tower motor | 0.75KW(water Pump)+0.25(Fan) |

A waste paper baling press machine is a piece of machinery used for recycling paper waste into bales. It typically consists of a series of rollers that transport the paper through a series of heated and compressed chambers, where the paper is compacted into bales. The bales are then separated from the residual paper waste, which can be recycled or reused as other paper products.

Waste paper baling press machines are commonly used in industries such as newspaper printing, packaging, and office supplies. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources.

The baling press for waste paper is a machine used in recycling facilities to compact and compress large amounts of paper waste into bales. The process involves feeding the waste paper into the machine, which then uses rollers to compress the material and form it into bales. Baling presses are commonly used in recycling centers, municipalities, and other facilities that handle large volumes of waste paper. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources

A waste paper baler is a machine used to compact and compress large amounts of waste paper into bales. The process involves feeding the waste paper into the machine, which then uses rollers to compress the material and form it into bales. Waste paper balers are commonly used in recycling centers, municipalities, and other facilities that handle large volumes of waste paper. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources.as more information ,pls visit us :https://www.nkbaler.com/

waste paper baling press is a machine used to compact and compress large amounts of waste paper into bales. The process involves feeding the waste paper into the machine, which then uses heated rollers to compress the material and form it into bales. Waste paper baling presses are commonly used in recycling centers, municipalities, and other facilities that handle large volumes of waste paper. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources.

Waste paper baling press machine is a piece of equipment used to recycle waste paper into bales. It is an essential tool in the recycling process, as it helps to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources. In this article, we will discuss the working principle, types of waste paper baling press machines, and their applications.

The working principle of waste paper baling press machine is relatively simple. The machine consists of several compartments where the waste paper is fed into. As the waste paper moves through the compartments, it is compacted and compressed by heated rollers, which form the bales. The bales are then separated from the residual paper waste, which can be recycled or reused as other paper products.

Waste paper baling press machines are widely used in industries such as newspaper printing, packaging, and office supplies. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources. In addition, they can also help to save energy and reduce costs for businesses that use paper products.

One of the key benefits of using a waste paper baling press machine is that it can help to improve the quality of the recycled paper. By compacting the waste paper into bales, it becomes easier to transport and store, reducing the risk of damage and contamination. This makes it easier for businesses to recycle their waste paper and ensures that they are able to produce high-quality paper products

In conclusion, waste paper baling press machines are an essential tool in the recycling process. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources. There are two main types of waste paper baling press machines: hot-air and mechanical, and they are widely used in industries such as newspaper printing, packaging, and office supplies. By using a waste paper baling press machine, businesses can improve the quality of their recycled paper and reduce their environmental impact.