NKW160Q Waste Paper Hydraulic Baling Press

NKW160Q Waste Paper Hydraulic Baling Press can be used for waste paper, waste cardboard boxes, straw, rice husk, cotton, waste cloth, woven bags, plastic bottles, cans, paint buckets and other materials。

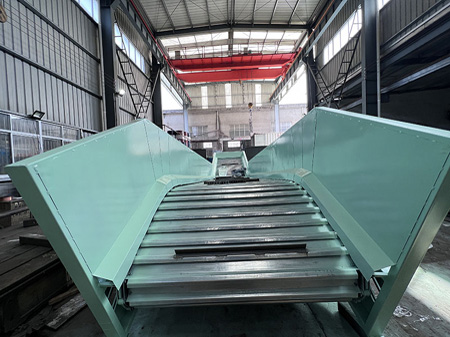

Waste Paper Hydraulic Baling Press is mainly composed of three parts: conveyor, baler, and discharge system. The material enters the main engine through the feeding conveyor and enters the hydraulic system.

Under the control of the system, the material is compressed into a fixed-volume baler, which is fixed by the automatic tape control and then sent out of the main machine under the action of the pusher cylinder to complete.The whole packaging job.

Nick Machinery fully automatic hydraulic baler has the advantages of fast speed, simple structure, stable movement, low failure rate and easy cleaning maintenance features.https://www.nkbaler.com

1. It is mainly suitable for compressing and packing loose materials such as waste paper edges, cartons, straw, wheat straw, etc. in printing factories.

2. Hydraulic configuration: private server system, low noise, low energy consumption, energy saving and environmental protection

3. Electrical configuration: PLC control is used to make the circuit simple, the failure rate is low, and the inspection and troubleshooting are simple and fast.

4. The length can be set freely, and the packing value can be accurately recorded.

5. The installation is simple, the foundation construction is simple, and no foundation reinforcement is required.

6. Feeding method: standard conveyor for refilling.

7. Can be customized according to customer needs.

|

Item |

Name |

parameter |

|

mainframe parameter |

Bale size | 1100mm(W)×1100mm(H)×~1600mm(L) |

| Material type | Scrap Kraft paper, Newspaper,Cardboard ,Soft Film, | |

| Material density | 500~600Kg/m3(Mositure12-18%) | |

| Feed opening size | 2400mm×1100mm | |

| Main motor power | 45KW+15KW | |

| Main cylinder | YG280/210-2900 | |

| Capacity | 12-15 ton /hour | |

| Main cylinder force | 160T | |

| Max. system working force | 30.5MPa | |

| Mainframe weight(T) | About 25 tons | |

| Oil tank | 2m3 | |

| Mainframe size | About 11×4.3×5.8M(L×W×H) | |

| Tie wire line | 4 line φ3.0~φ3.2mm3 iron wire | |

| Pressure time | ≤30S/ (go and back for empty load) | |

|

Chain conveyor technology |

Model | NK-III |

| Conveyor weight | About 7 tons | |

| Conveyor size | 2000*14000MM | |

| Conveyor motor | 7.5KW | |

|

Cool tower |

Cool tower motor | 0.75KW(water Pump)+0.25(Fan) |

A waste paper baling press machine is a piece of machinery used for recycling paper waste into bales. It typically consists of a series of rollers that transport the paper through a series of heated and compressed chambers, where the paper is compacted into bales. The bales are then separated from the residual paper waste, which can be recycled or reused as other paper products.

Waste paper baling press machines are commonly used in industries such as newspaper printing, packaging, and office supplies. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources.

The baling press for waste paper is a machine used in recycling facilities to compact and compress large amounts of paper waste into bales. The process involves feeding the waste paper into the machine, which then uses rollers to compress the material and form it into bales. Baling presses are commonly used in recycling centers, municipalities, and other facilities that handle large volumes of waste paper. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources

A waste paper baler is a machine used to compact and compress large amounts of waste paper into bales. The process involves feeding the waste paper into the machine, which then uses rollers to compress the material and form it into bales. Waste paper balers are commonly used in recycling centers, municipalities, and other facilities that handle large volumes of waste paper. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources.as more information ,pls visit us :https://www.nkbaler.com/

waste paper baling press is a machine used to compact and compress large amounts of waste paper into bales. The process involves feeding the waste paper into the machine, which then uses heated rollers to compress the material and form it into bales. Waste paper baling presses are commonly used in recycling centers, municipalities, and other facilities that handle large volumes of waste paper. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources.

Waste paper baling press machine is a piece of equipment used to recycle waste paper into bales. It is an essential tool in the recycling process, as it helps to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources. In this article, we will discuss the working principle, types of waste paper baling press machines, and their applications.

The working principle of waste paper baling press machine is relatively simple. The machine consists of several compartments where the waste paper is fed into. As the waste paper moves through the compartments, it is compacted and compressed by heated rollers, which form the bales. The bales are then separated from the residual paper waste, which can be recycled or reused as other paper products.

Waste paper baling press machines are widely used in industries such as newspaper printing, packaging, and office supplies. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources. In addition, they can also help to save energy and reduce costs for businesses that use paper products.

One of the key benefits of using a waste paper baling press machine is that it can help to improve the quality of the recycled paper. By compacting the waste paper into bales, it becomes easier to transport and store, reducing the risk of damage and contamination. This makes it easier for businesses to recycle their waste paper and ensures that they are able to produce high-quality paper products

In conclusion, waste paper baling press machines are an essential tool in the recycling process. They help to reduce the amount of waste sent to landfills and promote sustainable practices by recycling valuable resources. There are two main types of waste paper baling press machines: hot-air and mechanical, and they are widely used in industries such as newspaper printing, packaging, and office supplies. By using a waste paper baling press machine, businesses can improve the quality of their recycled paper and reduce their environmental impact.